|

|

|

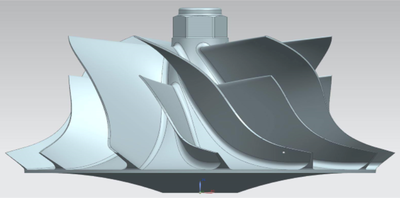

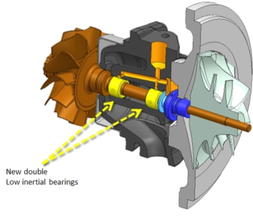

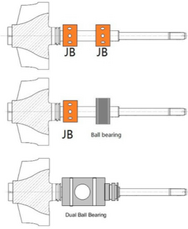

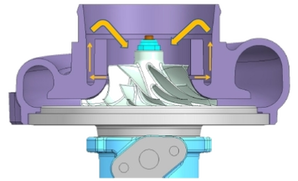

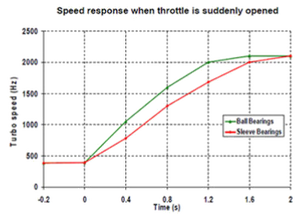

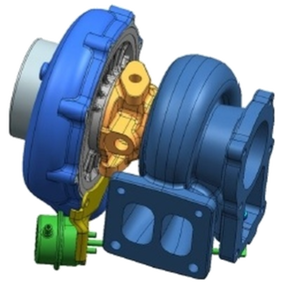

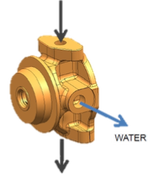

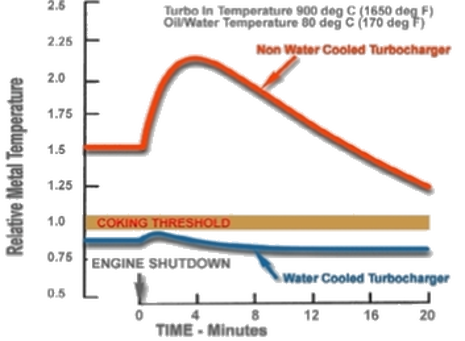

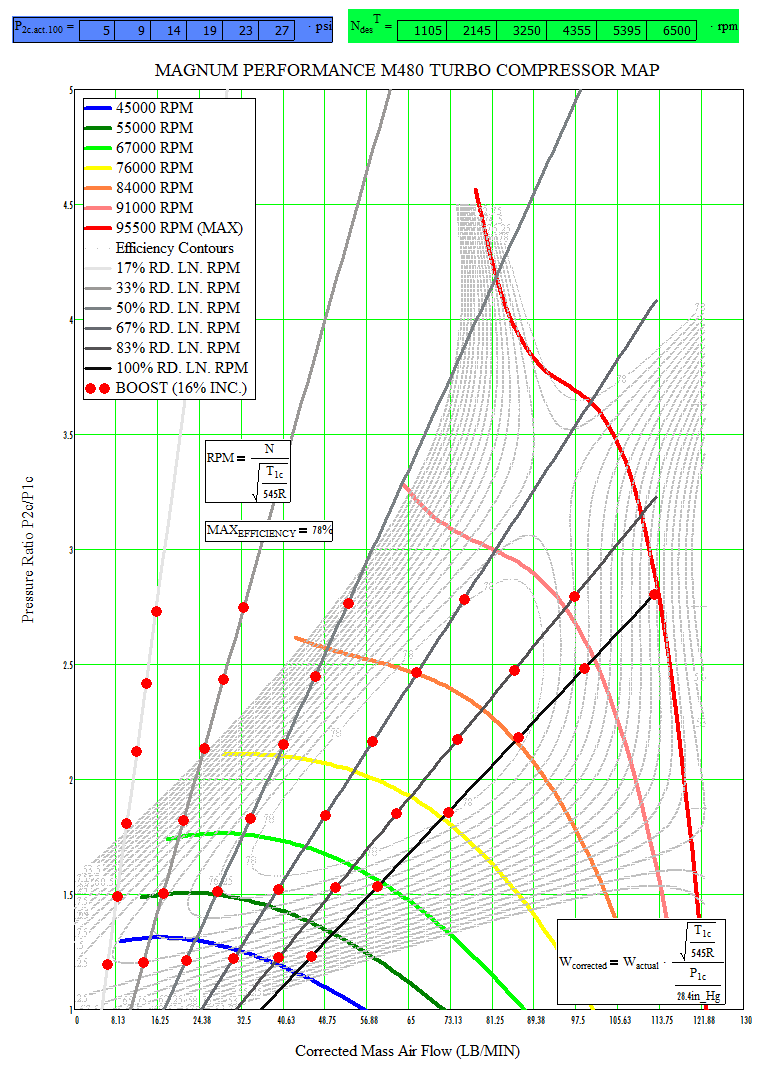

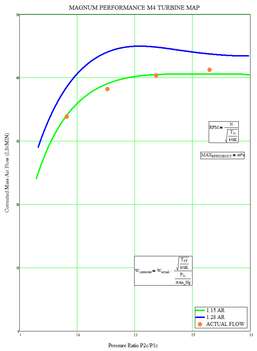

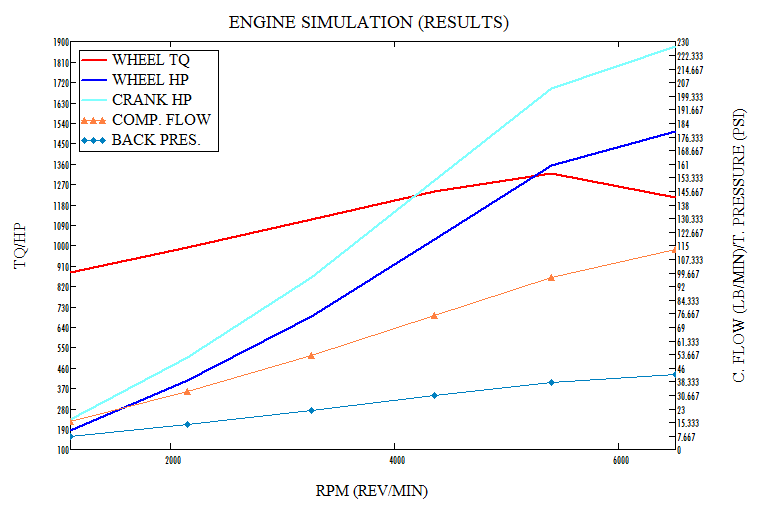

Magnum's emphasis on providing the highest quality products at unbeatable prices starts with our raw materials. From Magnum`s A2618 ultra lightweight aerospace grade aluminum billet wheels to our super alloy INCONEL 713C heat treated standard turbine shafts; it is no mystery why Magnum turbochargers are virtually fail proof. If that`s not enough order a custom Titanium Aluminide (Ti-Al) turbine wheel for your high performance applications and notice the Magnum Difference. Our Silicon-Nitride ball bearings and High Silicon-Molybdenum content housings are another great example of our dedication to perfection in the raw material selection process. However our ability to carry the industry`s best warranty doesn't just depend on proper material selection. Magnum`s Geometric design and exhaustive R&D driven engineering advances tell the rest of our story. At Magnum, we believe that great materials are only as good as the skilled technicians and engineers that mold them into a finished product. Our custom point milled billet compressor wheels and VSR balanced CHRAs come second to none. Thanks to Magnum's highly efficient twin scroll turbine housing geometry and anti-surged (Ported Shroud) compressor housing designs; lag has become a term of the past. Magnum Performance Turbos' revolutionary engine simulation software is one of a kind. Our unique ability to produce technical data that can be directly programmed into the vehicle's E.M.S. and anti-lag systems allows us to provide professional racing and tuning precision for the daily driver at a low cost. With today's advancements in turbocharger technology a properly trained tuner or technician with the technical support of a Magnum Turbo specialist can paint the exact power-band desired down to virtually a fraction of an RPM for their client.

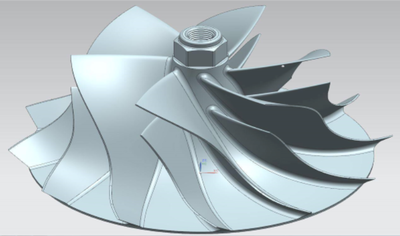

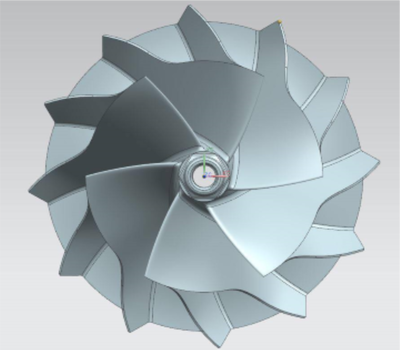

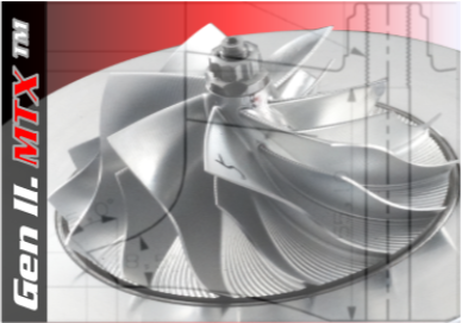

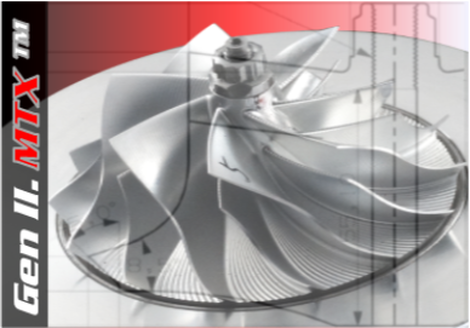

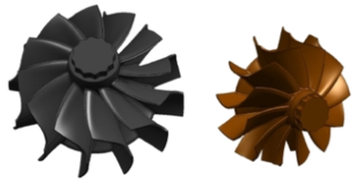

Magnum Performance Turbos strives to lead the industry in billet wheel technology. There are 3 basic advantages to Magnum Billet Wheels over standard C355 cast aluminum alloy compressor wheels. Considering that historically, the primary cause of turbocharger failure is Low Cycle Fatigue (LCF) failure in the compressor wheel. The real question is how do we manufacture a compressor wheel that is virtually exempt from the LCF phenomenon? Well, The "High-End" way is through using forged billet wheels that are manufactured from solid A2618 (aerospace grade) aluminum. This material alone provides ultra-low inertia, high tensile strength and ductility as is evident in the material's high strength to density (i.e; B/L) ratios. The "difficult" way is through lowering the circumferential speed of the compressor impeller by changing the aerodynamic design of the impeller or by controlling or reducing the charging pressure. Here at Magnum we are no stranger to choosing the road less traveled, hence we've employed both. The aerodynamic properties of our compressor wheels are second to none in our industry. But we don't stop there, our engine simulation software is the key to our unit's longevity. We run engine simulations custom to your application in order to maximize the lifespan of our units while providing the desired performance and power band for our customers. In layman's terms, you'll have a turbocharger that lasts virtually twice as long as that of one manufactured with a C355 cast aluminum compressor wheel with Magnum's Aerodynamic designs, free custom engine simulation and superior billet wheel materials.

|

As aforementioned, the aerodynamic properties of the billet wheel design has the second greatest impact on (LCF) resistance and service life. This is why the geometric design of a Point Milled Magnum Billet Wheel pushes the boundaries of performance with the industry leading 40.5 degree extended tip design. What does point milling mean to you? how does it differ from flank milling? Simple, unlike a flank milled wheel, a point milled wheel allows the designer to carry 3rd order (highly aerodynamic) geometries from the CAM/CAD software model to the CNC machine and make them a reality. This provides increased flow and reduces exducer tip speed allowing the turbo to spool faster and prevent long term low Cycle Fatigue Failure. But that's not it, by decreasing the trim and back plate rotating mass without reducing the inducer diameter it increases spool-up characteristics specially at low shaft speeds and reduces rotating mass inertia. Thereby reducing shaft stresses and increasing CHRA longevity.

|

A flank milled wheel, although a much better choice than cast wheels; provides very similar results as point milled wheels for nearly half the price. Our flank milled wheels exhibit the second highest degree extended tip in the industry 37.5 degree. Second only to our point milled designs of 40.5 degrees. These designs bring race proven results of the highest caliber and are available for our whole product line; making Magnum the obvious solution to your boosting needs. All this talk about extended tips beg the question...So what does an extended tip design do for you? Simple, increases flow by 15% which translates to an additional 15% crank horsepower while reducing lag.

|

Our proprietary engine simulation software was written and developed by Magnum Performance's U.S. (Florida) licensed professional engineers and is the result of over 2 years of brilliant work by our team. Over 600 pages of proprietary algorithms and formulas allow for such accurate results. This comes free with the purchase of your Magnum Performance Turbocharger from an authorized dealer.