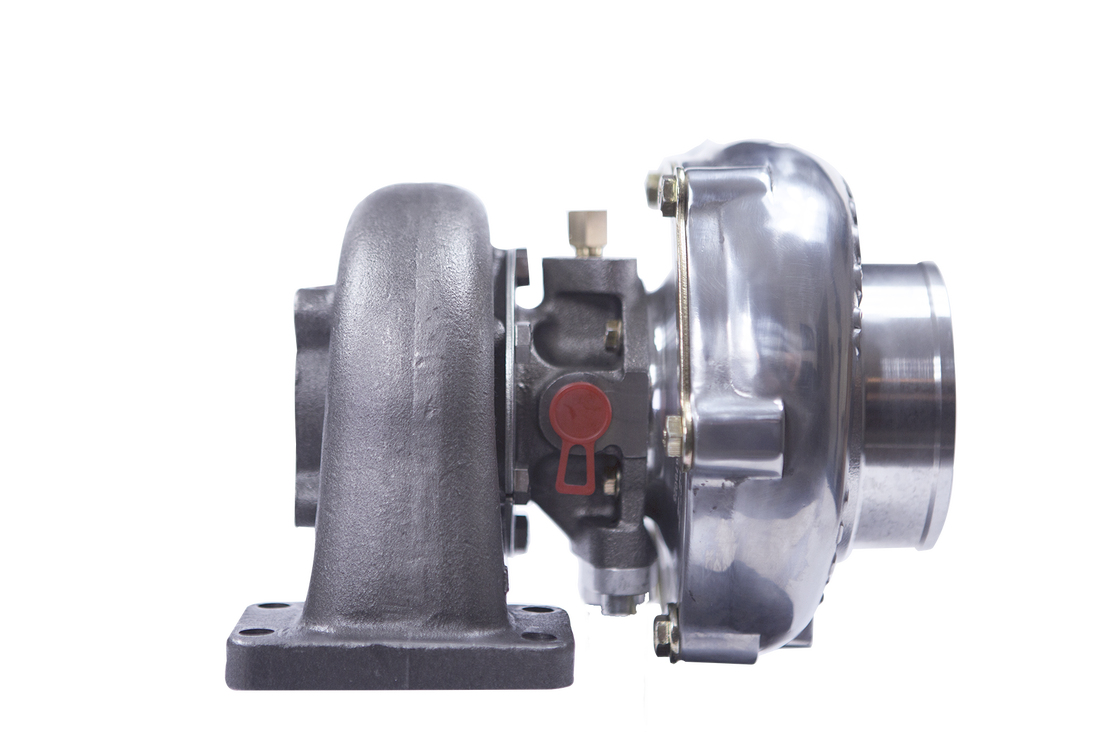

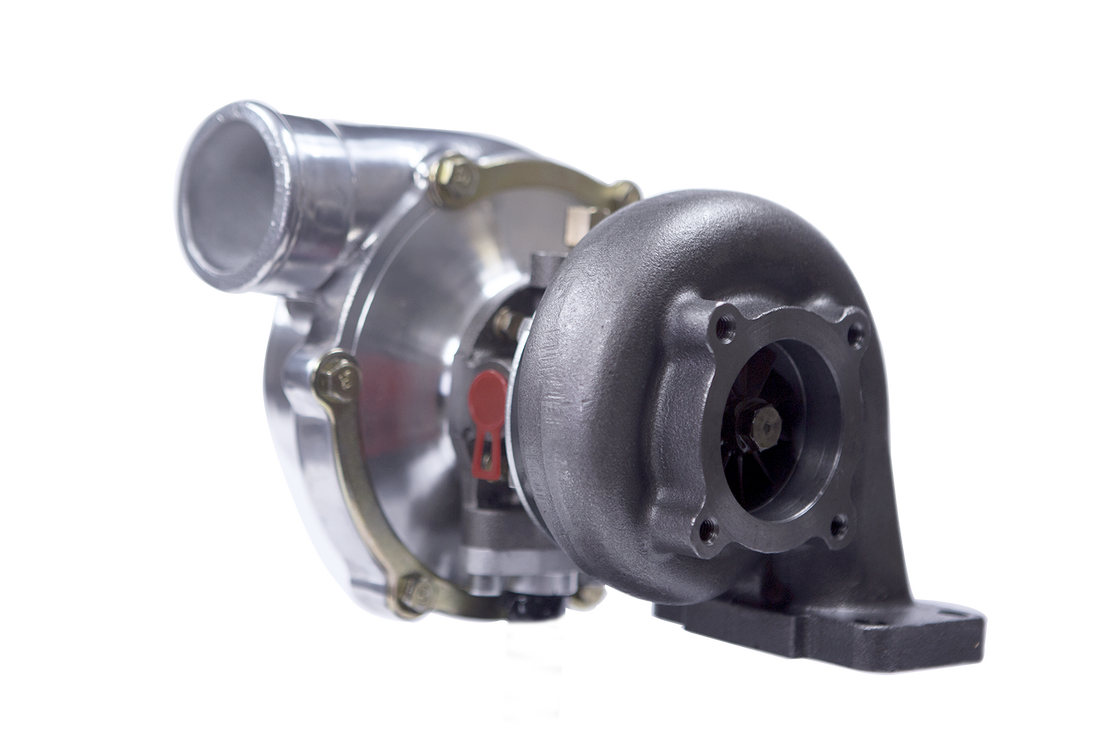

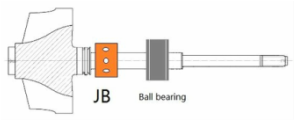

Hydrodynamic Journal Bearing Units (oil cooled only)

|

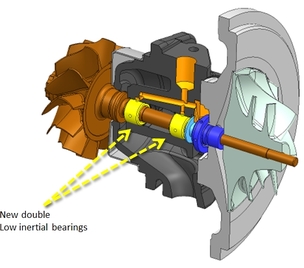

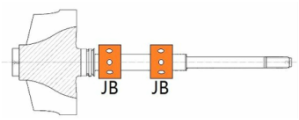

These units feature the industry's latest technological advances in Journal bearing Technology. Magnum's units come with low inertia dual hydrodynamic journal bearing technology. Manufactured out of high strength Copper-Tin alloy these "white metals" provide the highest scuffing and fatigue strength available while offering the lowest friction coefficient in comparable alloy groups. Generally, this bearing technology offers two primary advantages for the high performance market. The first being a low price-point that best suits the needs of amateur racers and racing enthusiast alike. Focused on wide open throttle response and serviceability this is easily the best option for the weekend hobbyist and street performance application. When taking into account that once target boost is achieved, ball bearings of any kind offer little to no advantage in performance at full throttle. This is the clear choice for seasoned drag racers not relying on the transient efficiency that a track car would need for example when trying to get out of a corner rapidly . Another often overlooked advantage of the journal bearing CHRA unit is it's serviceability. Unlike a Ceramic Ball Bearing CHRA which in most cases is not serviceable due to its irreparable failure modes. As a result this technology focuses on meeting the performance needs of most racers while offering a low price-point and relatively inexpensive repair or replacement cost in wearing parts. It's no wonder these units carry the best warranty in our lineup and industry as a whole.

|

Hybrid Ceramic Ball Bearing Units (water and oil cooled)

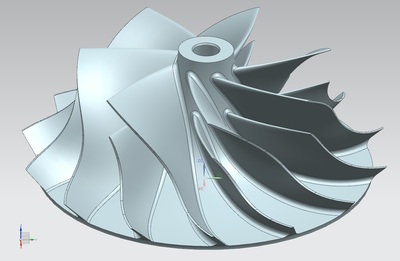

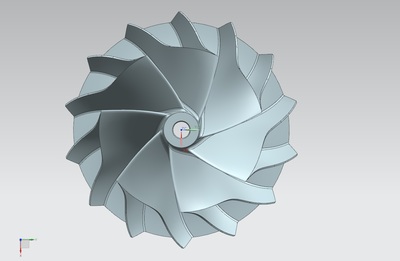

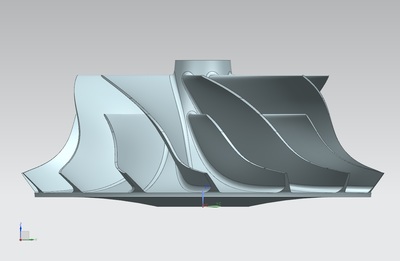

Flank Mill TechnologyThese models feature Magnum Performance's optional flank milled billet wheels which exhibit the highest degree angled extended tip in the industry 37.5 degrees. These designs bring race proven results of the highest caliber and are available for our whole product line making Magnum the obvious solution to your boosting needs. All this talk about extended tips beg the question...So what does an extended tip design do for you? Simple, increases flow by 15% which translates to an additional 15% crank horsepower.

|